Presentation Information

[O1-2]Recent advances in the development of high-performance HRE-free and RE-lean permanent magnets

*H. Sepehri Amin1, N. Kulesh1, J. Zhang1, Z. H. Kautsar1, A. Bolyachkin1, X. Tang1, H. Nakamura2, T. Ohkubo1, K. Hono1 (1. NIMS (Japan), 2. Shin-Etsu Chemical Co., Ltd. (Japan))

Keywords:

Nd-Fe-B magnets,SmFe12-based magnets,Microstructure,Coercivity

The demand for (Nd,Dy)-Fe-B permanent magnets is growing due to their applications in green energy conversion and transportation. To ensure sustainable long-term production, it is essential to reduce dependence on critical elements like Dy and diversify the use of rare earths while maintaining high coercivity and energy density in the magnets. In this talk, we will discuss how the integration of advanced materials processing, multi-scale microstructural characterization, FIB/SEM tomography-based micromagnetic simulations, and machine learning models has contributed to the development of high-performance permanent magnets that are free of heavy rare earths or contain minimal rare-earth content.

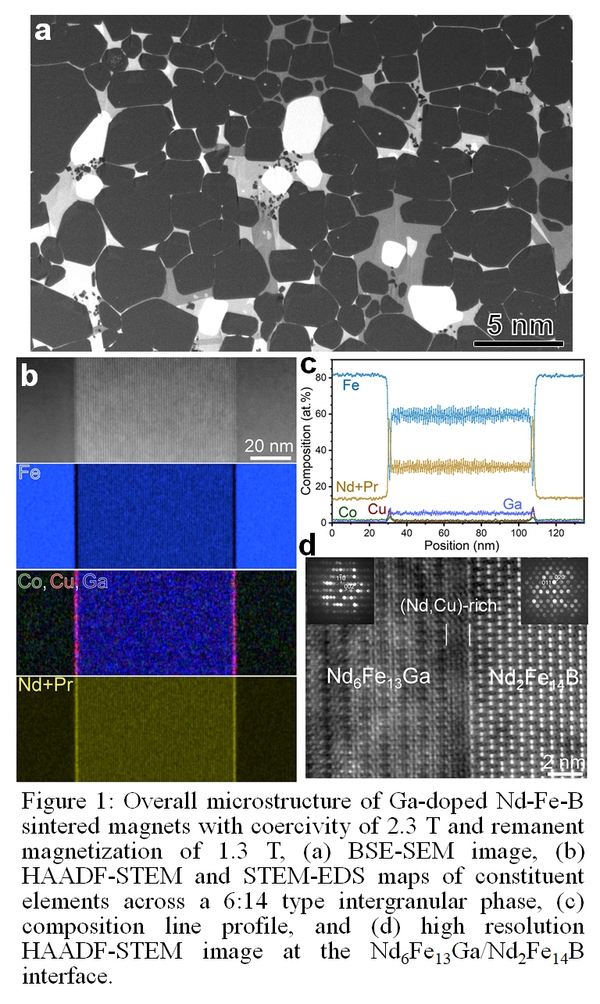

We will begin by presenting our research on developing high-coercivity Dy-free Nd-Fe-B magnets. Advances in hot-deformed Nd-Fe-B magnets have enabled grain size reduction to 125 nm in the lateral direction in anisotropic magnets, though coercivity remains limited to 2.0 T [1]. Micromagnetic simulations based on FIB/SEM tomography results have shown that the coercivity cannot be increased further even at this small grain size due to a pronounced effect of exchange coupling of Nd2Fe14B grains [1,2]. Grain boundary/interface engineering in the hot-deformed Nd-Fe-B magnets has led to a large coercivity of 2.5 T, remanent magnetization of 1.32 T, and excellent thermal stability of the coercivity [3]. Additionally, we will discuss how grain boundary engineering in sintered magnets has enhanced the coercivity in Ga-doped Nd-Fe-B sintered magnets to 2.3 T, with a remanent magnetization of 1.3 T. The overall microstructure of these magnets is shown in Figure 1.

In the second part of the talk, the potential of Fe-rich SmFe12-based magnets and the current challenges to realize these materials as new permanent magnets will be discussed. We will show our recent success in development of anisotropic bulk SmFe12-based sintered magnets with a coercivity of 1.0-1.5 T and remanent magnetization of 0.65-0.82 T assisted by machine learning [4-6]. Based on detailed microstructure characterizations, micromagnetic simulations, and modeled thin films, we will discuss the optimum microstructure which can lead to a larger coercivity and remanent magnetization in the SmFe12-based magnets. Finally, we will discuss future strategies in the development of permanent magnets that need to be considered in view of the emergence of new applications.

[1] N. Kulesh et al, Acta Mater. 276 (2024) 120159.

[2] A. Bolyachkin et al. Npj Comput Mater 10 (2024) 34

[3] M. Korent et al. Scripta Mater. 205 (2021) 114206.

[4] X. Tang, et al. Scripta Mater. 200 (2021) 113925.

[5] J. Zhang et al. Acta Mater. 238 (2022) 118228.

[6] A.K. Srinithi et al. Acta Mater. 256 (2023) 119111.

We will begin by presenting our research on developing high-coercivity Dy-free Nd-Fe-B magnets. Advances in hot-deformed Nd-Fe-B magnets have enabled grain size reduction to 125 nm in the lateral direction in anisotropic magnets, though coercivity remains limited to 2.0 T [1]. Micromagnetic simulations based on FIB/SEM tomography results have shown that the coercivity cannot be increased further even at this small grain size due to a pronounced effect of exchange coupling of Nd2Fe14B grains [1,2]. Grain boundary/interface engineering in the hot-deformed Nd-Fe-B magnets has led to a large coercivity of 2.5 T, remanent magnetization of 1.32 T, and excellent thermal stability of the coercivity [3]. Additionally, we will discuss how grain boundary engineering in sintered magnets has enhanced the coercivity in Ga-doped Nd-Fe-B sintered magnets to 2.3 T, with a remanent magnetization of 1.3 T. The overall microstructure of these magnets is shown in Figure 1.

In the second part of the talk, the potential of Fe-rich SmFe12-based magnets and the current challenges to realize these materials as new permanent magnets will be discussed. We will show our recent success in development of anisotropic bulk SmFe12-based sintered magnets with a coercivity of 1.0-1.5 T and remanent magnetization of 0.65-0.82 T assisted by machine learning [4-6]. Based on detailed microstructure characterizations, micromagnetic simulations, and modeled thin films, we will discuss the optimum microstructure which can lead to a larger coercivity and remanent magnetization in the SmFe12-based magnets. Finally, we will discuss future strategies in the development of permanent magnets that need to be considered in view of the emergence of new applications.

[1] N. Kulesh et al, Acta Mater. 276 (2024) 120159.

[2] A. Bolyachkin et al. Npj Comput Mater 10 (2024) 34

[3] M. Korent et al. Scripta Mater. 205 (2021) 114206.

[4] X. Tang, et al. Scripta Mater. 200 (2021) 113925.

[5] J. Zhang et al. Acta Mater. 238 (2022) 118228.

[6] A.K. Srinithi et al. Acta Mater. 256 (2023) 119111.