Presentation Information

[O3-1]Rare earth permanent magnets with high cerium content

*Dagmar Goll1, Ralf Loeffler1, Marius Boettle1, Gerhard Schneider1 (1. Aalen University (Germany))

Keywords:

Ce substitution,NdFeB,permanent magnets,rare-earth-based magnets,sintered magnets

The more effective use of readily available cerium in FeNdB sintered magnets is an important step towards more resource-efficient, sustainable, and cost-effective permanent magnets. These magnets have the potential to bridge the gap between high-performance (but expensive) FeNdB and cheap (but low-performance) hard ferrite magnets.

In sintered magnets, up to 30% of the Nd can be easily replaced by Ce [1, 2]. However, for higher degrees of Ce substitution, the magnetic properties deteriorate due to the poorer intrinsic magnetic properties of Fe14Ce2B compared to Fe14Nd2B and the pronounced formation of the Laves Phase Fe2Ce in the grain boundaries, which reduces the amount of the hard magnetic phase and the rare earth rich grain boundary phase [1]. Fe2Ce is paramagnetic for temperatures > - 43 °C and tends to aggregate at triple junctions of the hard magnetic 14:2:1 grains wetting them only to a limited extent. In addition, Fe2Ce may act as potential nucleation centers during magnetization reversal, thus diminishing the coercivity of the magnets. At very high Ce contents (> 80%), the soft magnetic Fe phase is precipitated resulting in even smaller coercive fields, especially when strip-cast flakes are used as the starting material [3]. In rapidly quenched magnets, on the other hand, Nd can be completely replaced by Ce (with good permanent magnet properties), as Fe2Ce formation is largely suppressed during rapid quenching [2]. However, rapidly quenched magnets are isotropic, so that their remanence is only about half that of sintered magnets. The positive influence of additives such as La, Si, Y on the magnetic properties has already been demonstrated on rapidly quenched magnets [2], which may also be of interest for the successful improvement of Ce-containing sintered magnets.

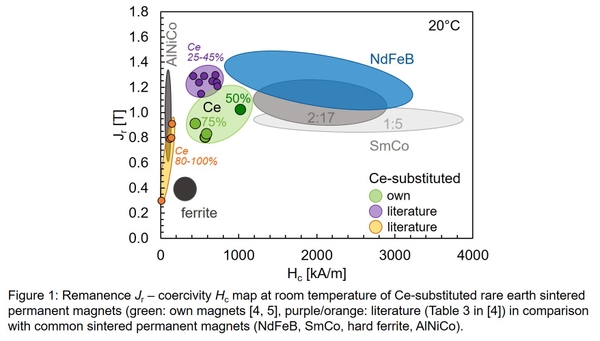

It is shown, that for single-alloy sintered magnets with a degree of Ce substitution of >= 50% of the composition (Ce, Nd)-Fe-B-M (M e.g. Co, Al) magnetic properties can be realized, which previous commercially available magnets have only shown for significantly lower degrees of Ce substitution (Fig. 1). The additional use of La enables tailoring of the microstructure and magnetic properties of sintered magnets with a high Ce content depending on the La content. E.g. the La-richest composition contains more 14:2:1 phase and significantly less Fe2Ce phase than the La-free variant. Using La as a dopant, the remanence could be increased by approximately 25%. At the same time, a new RE-rich grain boundary is formed and Laves phase fraction is reduced by up to 85%.

The talk summarizes the current state of the art and focuses on microstructure-property correlations, challenges and limits when Nd is substituted by Ce and on the positive influence of additives.

References

[1] A. Li, L. Xi, H. Feng, N. Zou, M. Tan, M. Zhu, W. Li, J. Iron Steel Res. Int. 27 (2020) 1

[2] G. Delette, J. Magn. Magn. Mater. 577 (2023) 170768

[3] D. Wang, A. Li, H. Feng, W. Li, Heliyon 10 (2024) e27245

[4] D. Goll, R. Loeffler, M. Boettle, J. Buschbeck, G. Schneider, Materials 17 (2024) 3110

[5] D. Goll, M. Boettle, J. Buschbeck, R. Loeffler, G. Schneider, Physica Status Solidi (RRL) Rapid Research Letters 18 (2024) 2400151

In sintered magnets, up to 30% of the Nd can be easily replaced by Ce [1, 2]. However, for higher degrees of Ce substitution, the magnetic properties deteriorate due to the poorer intrinsic magnetic properties of Fe14Ce2B compared to Fe14Nd2B and the pronounced formation of the Laves Phase Fe2Ce in the grain boundaries, which reduces the amount of the hard magnetic phase and the rare earth rich grain boundary phase [1]. Fe2Ce is paramagnetic for temperatures > - 43 °C and tends to aggregate at triple junctions of the hard magnetic 14:2:1 grains wetting them only to a limited extent. In addition, Fe2Ce may act as potential nucleation centers during magnetization reversal, thus diminishing the coercivity of the magnets. At very high Ce contents (> 80%), the soft magnetic Fe phase is precipitated resulting in even smaller coercive fields, especially when strip-cast flakes are used as the starting material [3]. In rapidly quenched magnets, on the other hand, Nd can be completely replaced by Ce (with good permanent magnet properties), as Fe2Ce formation is largely suppressed during rapid quenching [2]. However, rapidly quenched magnets are isotropic, so that their remanence is only about half that of sintered magnets. The positive influence of additives such as La, Si, Y on the magnetic properties has already been demonstrated on rapidly quenched magnets [2], which may also be of interest for the successful improvement of Ce-containing sintered magnets.

It is shown, that for single-alloy sintered magnets with a degree of Ce substitution of >= 50% of the composition (Ce, Nd)-Fe-B-M (M e.g. Co, Al) magnetic properties can be realized, which previous commercially available magnets have only shown for significantly lower degrees of Ce substitution (Fig. 1). The additional use of La enables tailoring of the microstructure and magnetic properties of sintered magnets with a high Ce content depending on the La content. E.g. the La-richest composition contains more 14:2:1 phase and significantly less Fe2Ce phase than the La-free variant. Using La as a dopant, the remanence could be increased by approximately 25%. At the same time, a new RE-rich grain boundary is formed and Laves phase fraction is reduced by up to 85%.

The talk summarizes the current state of the art and focuses on microstructure-property correlations, challenges and limits when Nd is substituted by Ce and on the positive influence of additives.

References

[1] A. Li, L. Xi, H. Feng, N. Zou, M. Tan, M. Zhu, W. Li, J. Iron Steel Res. Int. 27 (2020) 1

[2] G. Delette, J. Magn. Magn. Mater. 577 (2023) 170768

[3] D. Wang, A. Li, H. Feng, W. Li, Heliyon 10 (2024) e27245

[4] D. Goll, R. Loeffler, M. Boettle, J. Buschbeck, G. Schneider, Materials 17 (2024) 3110

[5] D. Goll, M. Boettle, J. Buschbeck, R. Loeffler, G. Schneider, Physica Status Solidi (RRL) Rapid Research Letters 18 (2024) 2400151