Presentation Information

[O3-4]Grain boundary diffusion of gas-atomized Nd-Pr-Al-Cu powders on Nd2Fe14B-based magnets

*Carter Tesch1, Balamurugan Balasubramanian1 (1. Hoeganaes Corportation, 1001 Taylors Ln, Cinnaminson, NJ 08077 (United States of America))

Keywords:

Grain boundary diffusion,Light rare earth alloy

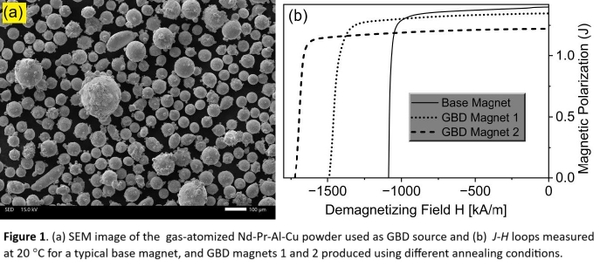

Nd2Fe14B-based magnets are used in a wide range of applications including high-performance electric motors, wind turbines, electronics and information technology, advance medical equipment, and home appliances. For EV motor applications, a replacement of Nd with scarce and expensive heavy rare-earth elements (HREEs) such as Dy and Tb is essential to retain desired coercivity and performance of NdFeB magnets at elevated operating temperatures (Top), typically around or above 120 °C. Addition of HREEs via grain boundary diffussion (GBD) process significantly reduces their usage in NdFeB magnets. GBD process can be applied to diffuse light rare-earth eutectic (LREE) alloys into NdFeB magnets and has potential to achieve higher coercivities without HREEs in the GBD magnets. In this study, LREE alloy powders were produced by Electrode Induction melting Gas Atomization (EIGA) method and used as GBD source to produce HREE-free magnets with significantly improved coercivities and operating temperatures. Gas atomization provides a good control over morphology, phase, size, and size-distribution of LREE alloy powders, and these powders can be easily adapted for large-scale adhesive coating methods including spraying or dip coating, painting, and screen printing. Figure 1(a) shows a scanning electron microscope image of atomized Nd-Pr-Al-Cu powders with d50 = 32 um, which were slurry-coated on (NdPr)30.1FeBal(CoCuGaAlTiSiNiZr)1.09B0.97 magnets and subsequently diffused via GBD annealing. Upon grain boundary diffussion of Nd-Pr-Al-Cu and varying the annealing conditions and diffused contents, the coercivity of magnets increases significantly from 1085 to 1724 kA/m, improving the magnet from normal coercivity grade (Top = 80 °C) to super-high (SH) coercivity grade (Top = 150 °C) as shown in Fig. 1(b). The effect of the diffused Nd-Pr-Al-Cu content on the magnetic properties of GBD magnets, such as coercivity and remanent induction and their reversible temperature coefficients, will be discussed.