Presentation Information

[O4-4]Unraveling the nanostructure and coercivity mechanism of single-phase Ce(Co0.8Cu0.2)5.4 hard magnet

*Tatiana Smoliarova1, András Kovács2, Nikita Polin3, Xinren Chen3, Esmaeil Adabifiroozjaei4, Leopoldo Molina-Luna4, Oliver Gutfleisch4, Konstantin Skokov4, Michael Farle1, Baptiste Gault3, Rafal E Dunin-Borkowski2 (1. Faculty of Physics and Center for Nanointegration, Universität Duisburg-Essen, Duisburg, Germany (Germany), 2. Ernst Ruska-Centre for Microscopy and Spectroscopy with Electrons, Forschungszentrum Jülich, Germany (Germany), 3. Max-Planck-Institut für Nachhaltige Materialien GmbH, Düsseldorf 40237, Germany (Germany), 4. Institute of Materials Science, Technische Universität Darmstadt, 64287 Darmstadt, Germany (Germany))

Keywords:

RCo5,TEM,APT,Off-axis electron holography

The use of Ce in RCo5 magnets has recently drawn attention due to the relative abundance of Ce among rare-earth (R) elements. However, CeCo5 exhibits lower saturation magnetization (MS = 62.2 A·m2/kg [1]), reduced Curie temperature (TC = 650 K [1]), and smaller anisotropy constant (K1 = 7.2 MJ/m3 [2]) compared to SmCo5 (MS = 102.4 A·m²/kg, TC = 1020 K, K1 = 17.2 MJ/m3 [3]). Despite these intrinsic limitations, recent advances [4, 5] in material engineering have significantly improved its coercivity, making it a promising abundant alternative to Sm-based magnets. Thus, upon addition of Cu up to 20% to CeCo5 significantly enhances coercivity, achieving values of around µ0HC = 1 T, which is ~70 % higher compared to pure CeCo5 (µ0HC = 0.274 T).

In this work, the correlation between nanostructure and magnetic properties of the off-stoichiometric Ce(Co0.8Cu0.2)5.4 magnet was studied using transmission electron microscopy (TEM) in conjunction with atom probe tomography (APT).

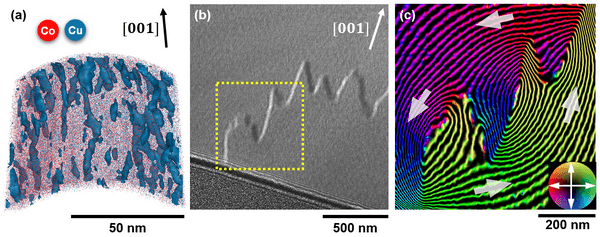

The magnet was prepared by induction melting, followed by controlled heat treatment and water quenching. Cu doping leads to a partial substitution of Co atoms by Cu atoms, resulting in the formation of a compositionally modulated nanostructure. This structure consists of elongated Cu-poor cylindrical precipitates (~5 nm in diameter, ~20 nm in length) surrounded by a Cu-rich matrix (~10 nm thick) (Fig. (a)). Cu-poor cylindrical precipitates are aligned along the c-axis of the CeCo5 hexagonal (P6/mmm) unit cell, which coincides with the uniaxial magnetic anisotropy axis. This nanostructure creates alternating regions of different magnetic properties, providing a preferential pathway for domain wall (DW) pinning.

The magnetic domain configuration was studied using magnetic contrast measurements in TEM on electron-transparent specimen in magnetic-field-free conditions. The electron-transparent Ce(Co0.8Cu0.2)5.4 specimen was prepared from a single grain along the uniaxial [001] direction to minimize the influence of shape anisotropy. Figure (b) presents an underfocus (1 mm) Fresnel image, recorded at magnetic remanence, revealing zigzag or ‘saw-tooth’ DWs (DWs) [6, 7]. These DWs formed following the application of a 1 T external field along the [001] direction. The DWs appear as bright (convergent) or dark (divergent) contrast bands, depending on the local magnetization direction. The zigzag DW configuration is commonly observed in magnetic single crystals with in-plane uniaxial magnetic anisotropy and occurs between two areas of oppositely directed magnetization [8].

To study the local magnetic field distribution, off-axis electron holography was employed to map the in-plane magnetic induction associated with the observed DWs. The in-plane magnetic field distribution is obtained from the phase shift of the electron wave and is visualized as a magnetic induction map on the assumption that the electrostatic phase shift is constant for a single crystalline specimen. Fig. (c) shows an in-plane magnetic induction map of the region highlighted with the yellow dotted square in fig. (b), where the magnetic induction is depicted using contour lines at the positions of the equiphase contours, complemented by color coding. The zigzag DW consists of straight segments where the central part exhibits a 180° rotation of magnetization with a DW width (δW) of 4.3 ± 0.6 nm, while two tails of a segment show magnetic field rotation closer to 90°. According to the model proposed by Finzi and Hartmann [9], this structure can be described as a 180° Bloch wall spine flanked by Néel tails on either side, which helps to minimize magnetostatic energy by redistributing magnetic charges.

The zigzag DW pinning in Ce(Co0.8Cu0.2)5.4 magnet is associated with the compositionally modulated nanostructure, in which spatial variation in magnetic properties results in preferential DW pinning at Cu-rich boundaries and adopts a non-linear trajectory. This arrangement reduces magnetostatic energy while stabilizing the pinned domain structure, further contributing to the Ce(Co0.8Cu0.2)5.4 magnet coercivity µ0HC = 1 ± 0.05 T.

Financial support by DFG, CRC/TRR 270 (project ID 405553726) is acknowledged.

[1] Nordström, Phys. Rev. B. 41.13 (1990): 9111.

[2] Bartashevich, J. Magn. Magn. Mater. 131(1), (1994): 61-66.

[3] Coey, IEEE Trans. Magn. 47(12), (2011): 4671. A.

[4] Nesbitt, J. Appl. Phys. 40.3 (1969): 1259-1265.

[5] Leamy, IEEE Trans. Magn. 23.7 (1973): 409-410.

[6] Hubert and Schäfer, Springer, (1998): 255.

[7] Taylor, IEEE Trans. Magn. 16(5), (1980): 902-904.

[8] Favieres, J. Phys.: Condens. Matter 25, (2013): 066002.

[9] Finzi and Hartmann, IEEE Trans. Magn. 4, (1968): 662.

In this work, the correlation between nanostructure and magnetic properties of the off-stoichiometric Ce(Co0.8Cu0.2)5.4 magnet was studied using transmission electron microscopy (TEM) in conjunction with atom probe tomography (APT).

The magnet was prepared by induction melting, followed by controlled heat treatment and water quenching. Cu doping leads to a partial substitution of Co atoms by Cu atoms, resulting in the formation of a compositionally modulated nanostructure. This structure consists of elongated Cu-poor cylindrical precipitates (~5 nm in diameter, ~20 nm in length) surrounded by a Cu-rich matrix (~10 nm thick) (Fig. (a)). Cu-poor cylindrical precipitates are aligned along the c-axis of the CeCo5 hexagonal (P6/mmm) unit cell, which coincides with the uniaxial magnetic anisotropy axis. This nanostructure creates alternating regions of different magnetic properties, providing a preferential pathway for domain wall (DW) pinning.

The magnetic domain configuration was studied using magnetic contrast measurements in TEM on electron-transparent specimen in magnetic-field-free conditions. The electron-transparent Ce(Co0.8Cu0.2)5.4 specimen was prepared from a single grain along the uniaxial [001] direction to minimize the influence of shape anisotropy. Figure (b) presents an underfocus (1 mm) Fresnel image, recorded at magnetic remanence, revealing zigzag or ‘saw-tooth’ DWs (DWs) [6, 7]. These DWs formed following the application of a 1 T external field along the [001] direction. The DWs appear as bright (convergent) or dark (divergent) contrast bands, depending on the local magnetization direction. The zigzag DW configuration is commonly observed in magnetic single crystals with in-plane uniaxial magnetic anisotropy and occurs between two areas of oppositely directed magnetization [8].

To study the local magnetic field distribution, off-axis electron holography was employed to map the in-plane magnetic induction associated with the observed DWs. The in-plane magnetic field distribution is obtained from the phase shift of the electron wave and is visualized as a magnetic induction map on the assumption that the electrostatic phase shift is constant for a single crystalline specimen. Fig. (c) shows an in-plane magnetic induction map of the region highlighted with the yellow dotted square in fig. (b), where the magnetic induction is depicted using contour lines at the positions of the equiphase contours, complemented by color coding. The zigzag DW consists of straight segments where the central part exhibits a 180° rotation of magnetization with a DW width (δW) of 4.3 ± 0.6 nm, while two tails of a segment show magnetic field rotation closer to 90°. According to the model proposed by Finzi and Hartmann [9], this structure can be described as a 180° Bloch wall spine flanked by Néel tails on either side, which helps to minimize magnetostatic energy by redistributing magnetic charges.

The zigzag DW pinning in Ce(Co0.8Cu0.2)5.4 magnet is associated with the compositionally modulated nanostructure, in which spatial variation in magnetic properties results in preferential DW pinning at Cu-rich boundaries and adopts a non-linear trajectory. This arrangement reduces magnetostatic energy while stabilizing the pinned domain structure, further contributing to the Ce(Co0.8Cu0.2)5.4 magnet coercivity µ0HC = 1 ± 0.05 T.

Financial support by DFG, CRC/TRR 270 (project ID 405553726) is acknowledged.

[1] Nordström, Phys. Rev. B. 41.13 (1990): 9111.

[2] Bartashevich, J. Magn. Magn. Mater. 131(1), (1994): 61-66.

[3] Coey, IEEE Trans. Magn. 47(12), (2011): 4671. A.

[4] Nesbitt, J. Appl. Phys. 40.3 (1969): 1259-1265.

[5] Leamy, IEEE Trans. Magn. 23.7 (1973): 409-410.

[6] Hubert and Schäfer, Springer, (1998): 255.

[7] Taylor, IEEE Trans. Magn. 16(5), (1980): 902-904.

[8] Favieres, J. Phys.: Condens. Matter 25, (2013): 066002.

[9] Finzi and Hartmann, IEEE Trans. Magn. 4, (1968): 662.