Presentation Information

[P2-18]Demagnetization process of Sm(FeCo)12/α-Fe grains with a gradient structure

*Kunihiro KOIKE1, Yishan QIAO1, Nobuyuki INABA1, Hiroaki KATO1, Masaru Itakura2, Msaki NAKANO3, Susumu Okubo4, Hitoshi Ohta4 (1. Yamagata University (Japan), 2. Kyushu University (Japan), 3. Nagasaki University (Japan), 4. Kobe University (Japan))

Keywords:

Permanent magnets,Nanocomposites,Micromagnetics,Demagnetization processes

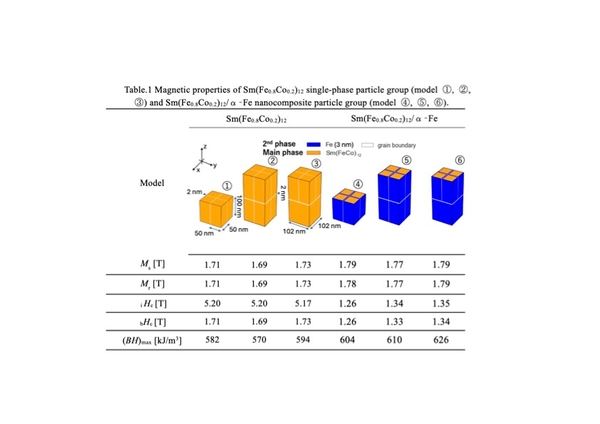

Although the use of high-performance Nd-Fe-B permanent magnets is increasing, it is predicted that the stable supply of neodymium will become difficult in the near future, and there is a strong demand for reducing the amount of Nd used and developing new permanent magnets to replace Nd [1]. In this context, the Sm(Fe0.8Co0.2)12 phase, which has a ThMn12-type structure and uses the relatively inexpensive Sm element, has a higher saturation magnetization Ms and uniaxial magnetocrystalline anisotropy Ku than Nd2Fe14B, and a higher Curie point Tc, and is expected to be a candidate for the main phase of next-generation magnets [2]. We investigated the demagnetization process in exchange-coupled nanocomposite single grains with a Sm(Fe0.8Co0.2)12 phase side-coated with an α-Fe phase using the micromagnetic simulator, and reported on the conditions that produce a larger maximum energy product (BH)max than that of a Sm(Fe0.8Co0.2)12 single-phase particle [3]. However, this calculation was based on a single particle, and did not fully consider the effect of the microstructure, which is composed of multiple phases such as the main phase, secondary phase, and grain boundary phase, on the magnetic properties of the permanent magnets. In this report, we focus on a magnet model with a microstructure in which exchange coupling between the main phase grains is separated by a non-magnetic grain boundary phase. We investigate the demagnetization process in Sm(Fe0.8Co0.2)12 single-phase grains with multiple different microstructures and exchange-coupled Sm(Fe0.8Co0.2)12/α-Fe nano-composite grains, as shown in Table 1, using the Mumax3 micromagnetic simulator [4]. The magnetic properties obtained from the simulation of the demagnetization process for models ① to ⑥ are summarized in Table 1. In all the models, the exchange coupling between the main phase grains was disconnected, and a high iHc was obtained. In particular, in the single-phase grains, the reduction in iHc for model ③, which has a gradient structure, was about 3% compared to models ① and ②, and as a notable point, Ms increased by about 2.4%, and (BH)max also increased by 4.2%. On the other hand, a more important result is that among the nanocomposite grains, model ⑥, which has a gradient structure, exhibits a larger iHc than models ④ and ⑤. In addition, the nanocomposite grains contain α-Fe with a larger Ms value than that of the Sm(Fe0.8Co0.2)12 phase, resulting in an Ms approximately 10% larger than that of the single-phase particles. Notably, the (BH)max was the largest among all models, with an increase of 9.82% compared to model ②.

References

[1] S. Hirosawa et al., Adv. Nat. Sci: Nanosci. Nanotechnol., 8, (2017) 013002.

[2] Y. Hirayama et al., Scr. Mater., 138, (2017) 62.

[3] R. Uda and K. Koike et al., AIP Advances 13(2), (2023) 025311.

[4] A. Vansteenkiste et al., AIP Advances 4(10) (2014) 107133.

References

[1] S. Hirosawa et al., Adv. Nat. Sci: Nanosci. Nanotechnol., 8, (2017) 013002.

[2] Y. Hirayama et al., Scr. Mater., 138, (2017) 62.

[3] R. Uda and K. Koike et al., AIP Advances 13(2), (2023) 025311.

[4] A. Vansteenkiste et al., AIP Advances 4(10) (2014) 107133.