Presentation Information

[O9-5]Low temperature densification of Nd(Fe,Mo)12 nitrided samples

Gabriel Gomez Eslava1, Patricia de Rango2, *Sorana Luca1 (1. Univ. Grenoble Alpes, CEA, Liten, F-38000 Grenoble (France), 2. Univ. Grenoble Alpes, CNRS, Institut Néel, 38000 Grenoble (France))

Keywords:

TR-Fe12 compounds,low temperature densification,eutectic alloys

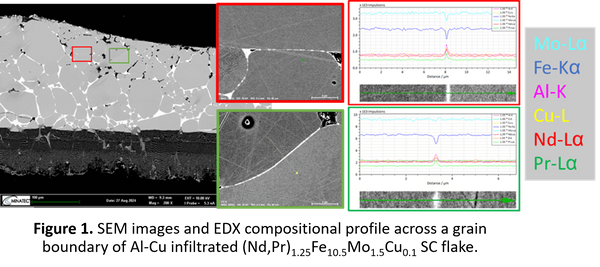

The family of intermetallics with general formula RE-Fe12 (RE = rare-earth) is considered as the strongest candidate for alternative high performance permanent magnet. Among all the existent compounds, the Nd-based ones are of particular interest due to their high saturation magnetization, high magnétocristalline anisotropy and Curie temperature in the nitrided powders. However, the nitrided Nd-based 1:12 phase decomposes at 650°C [1], making the densification of a permanent magnet a challenging task. To overcome this limitation, we developed low temperature densification processes for the Nd(Fe,Mo)12-based powders, thanks to the Grain Boundary (GB) low temperature eutectic alloys. Therefore, the insertion of low temperature eutectic alloys is a fundamental piece of the puzzle. Several binary eutectic alloys were identified, i.e., La-Cu and Al-Cu, that respond to two fundamental requirements: (i) their constituents have limited or none solubility in the 1:12 phase and (ii) their eutectic temperature should be lower than the decomposition temperature of the 1:12 phase. Our preliminary studies had shown that Cu is not soluble into the 1:12 Nd(Fe,Mo)12 phase, and forms eutectic alloys with the excess of RE [2]. In addition, no 1:12 phase can be stabilized with La at the RE site [3]. In the case of Al, it is a possible stabilizing element of the 1:12 phase, which is in any case already stabilized by the presence of Mo. It is thus expected that at low temperatures it will not substitute Mo. Infiltration experiments of the above mentioned alloys were carried out, by putting in contact the binary alloys (powder or flakes) with Cu-rich Nd(Fe,Mo)12 SC flakes. The thermal treatment for infiltration was performed in vacuum below 600°C, during 12 h. No significant changes in the microstructure of the SC flake was detected. Infiltration of the La-Cu has been evidenced by SEM-EDX mapping, on all the flake’s thickness (~150 µm). SEM images and compositional maps acquired by EDX analysis of an Al-Cu infiltrated sample are presented in fig. 1. The only modification of the microstructure is the appearance of thin grain boundary layers separating adjacent grains, even in the regions where initially no grain boundary was observed. EDX compositional maps reveal the presence of Al only at the GB region all across the SC flake, together with Cu and Nd/Pr. This promising result suggest that Al could be used for the production of low temperature eutectic phase at the GB’s. In addition, Nd/Pr – rich GB phase with a low Fe content suggests the formation of non-magnetic GB phase, which is beneficial for the magnetic decoupling of 1:12 adjacent grains.

Spark Plasma Sintering (SPS) experiments were carried out by mixing the nitride SC powders and Al-Cu powders at different volume ratios. Parts produced at 600°C – 70 MPa with 25 vol% of Al-Cu powder show good mechanical stability, with density of 5.13 g/cm3 that represents 73% of the theoretical density, which could be improved by high pressure SPS. Densification at 83% was obtained in a first test at 1.7 GPa at room temperature that can be improved by densifying at higher temperatures. Microstructural analysis and magnetic properties of aligned densified samples will be reported at the conference. Our promising results show that low temperature densification of nitrided NdFe12-based compounds are feasible by the inclusion of eutectic alloys. Powder-to-powder method combined with high pressure SPS could lead to an improved density in the final parts. In a second step, we aim to including the identified components, i.e. Ga, La, Cu and Al, during the preparation of the SC ribbons, in order to improve the microstructure and simplify the low-temperature densification process.

References:

[1] A. Aubert et al., ‘Phys. Rev. Mater., vol. 5, no. 1, p. 014415, Jan. 2021; doi:10.1103/PhysRevMaterials.5.014415.

[2] S. Luca et al., Journal of Alloys and Compounds 1010 (2025) 178039; doi.org/10.1016/j.jallcom.2024.178039

[3] A.M. Gabay et al. Journal of Alloys and Compounds 683 (2016) 271; doi.org/10.1016/j.jallcom.2016.05.092

Spark Plasma Sintering (SPS) experiments were carried out by mixing the nitride SC powders and Al-Cu powders at different volume ratios. Parts produced at 600°C – 70 MPa with 25 vol% of Al-Cu powder show good mechanical stability, with density of 5.13 g/cm3 that represents 73% of the theoretical density, which could be improved by high pressure SPS. Densification at 83% was obtained in a first test at 1.7 GPa at room temperature that can be improved by densifying at higher temperatures. Microstructural analysis and magnetic properties of aligned densified samples will be reported at the conference. Our promising results show that low temperature densification of nitrided NdFe12-based compounds are feasible by the inclusion of eutectic alloys. Powder-to-powder method combined with high pressure SPS could lead to an improved density in the final parts. In a second step, we aim to including the identified components, i.e. Ga, La, Cu and Al, during the preparation of the SC ribbons, in order to improve the microstructure and simplify the low-temperature densification process.

References:

[1] A. Aubert et al., ‘Phys. Rev. Mater., vol. 5, no. 1, p. 014415, Jan. 2021; doi:10.1103/PhysRevMaterials.5.014415.

[2] S. Luca et al., Journal of Alloys and Compounds 1010 (2025) 178039; doi.org/10.1016/j.jallcom.2024.178039

[3] A.M. Gabay et al. Journal of Alloys and Compounds 683 (2016) 271; doi.org/10.1016/j.jallcom.2016.05.092