Presentation Information

[O10-3]Study of magnetization reversal and magnetic hardening in SmCo5 single crystal magnet

*Alex Aubert1, Hongguo Zhang1,2, Fernando Maccari1, Christian Dietz3, Ming Yue2, Konstantin Skokov1, Oliver Gutfleisch1 (1. Functional Materials, TU Darmstadt (Germany), 2. Faculty of Materials and Manufacturing, Beijing University of Technology (China), 3. Physics of Surfaces, TU Darmstadt (Germany))

Keywords:

SmCo5,Single crystal magnets,Magnetization reversal

In permanent magnets, magnetization reversal typically involves two crucial fields: the nucleation field (Hn), which is necessary to introduce a reversal domain into a magnetically saturated crystal, and the (de-)pinning field (Hp), required to release a trapped wall from its pinning sites [1]. However, distinguishing between a true nucleation process and a local "de-pinning" of an existing wall can sometimes be challenging, both experimentally and conceptually. In sintered magnets, the process of magnetization reversal in Nd2Fe14B or SmCo5 magnets is traditionally attributed to the nucleation of reversal magnetic domains at the surface defects of single crystalline grains. However, recent findings challenge this assertion, primarily based on measurements of the angular dependence of coercivity, which follows a pinning-type Kondorsky model attributed to domain wall pinning at grain boundary interfaces [2]. To clarify this point, a more in-depth understanding of nucleation processes is needed and studying "ideal" objects with minimal defects can provide valuable insights.

In fact, traditional sintered magnets are highly complex objects, often featuring multiple phases, grain boundaries, varied grain sizes and shapes, misaligned grains etc. The magnetization reversal is thus a combination of various effects. The nucleation can arise from high local demagnetizing fields due to surface irregularities, structural defects, secondary phases etc. which can lead to a drastic reduction of the local anisotropy. To properly isolate the effects of nucleation and pinning and better understand their contributions, an ideal experimental system is required. Large, high-quality single crystals provide a good opportunity to study magnetization reversal in the absence of grain boundaries and other microstructural complexities inherent to sintered magnets.

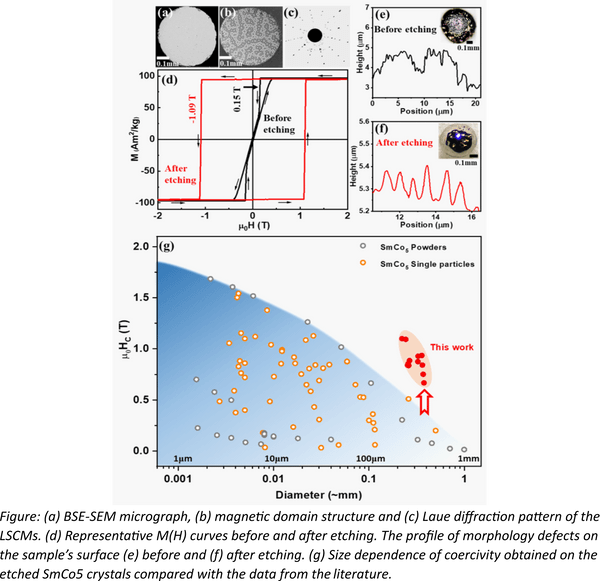

In this study, we synthesis large single-crystal magnets of SmCo5 with high-quality surfaces to investigate their magnetization reversal process. After surface treatment by electro-polishing, the SmCo5 magnets exhibit a significantly increased coercivity reaching values close to 1 T, and are two to ten times larger in size compared to previous reports with similar coercivity (see Figure). We delve into the origin of this large coercivity and examine the detailed influence of surface conditions and different nucleation processes. We discuss the effect of type-I (local depining) and type-II (true nucleation) nucleus and their impact in magnetization reversal of our objects. Lastly, we explore the angular dependence of coercivity in these ideal objects, assessing the method's applicability for more complex systems like sintered magnets. In summary, we present ideal single crystal permanent magnet of SmCo5 which can help us understand deeper the coercivity mechanism (nucleation, pinning) and the role of surface (im)perfection [3].

References

[1] Chikazumi, JMMM 54-57, 1551 (1986)

[2] J. Li, H. Sepehri-Amin, et al , STAM 22:1 386-403 (2021)

[3] H. Zhang, A. Aubert et al. JALCOM 993 174570 (2024)

Acknowledgement:

This work was supported by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation), Project ID no. 405553726-TRR 270 and the National Key R&D Program of China (2023YFB3508500).

In fact, traditional sintered magnets are highly complex objects, often featuring multiple phases, grain boundaries, varied grain sizes and shapes, misaligned grains etc. The magnetization reversal is thus a combination of various effects. The nucleation can arise from high local demagnetizing fields due to surface irregularities, structural defects, secondary phases etc. which can lead to a drastic reduction of the local anisotropy. To properly isolate the effects of nucleation and pinning and better understand their contributions, an ideal experimental system is required. Large, high-quality single crystals provide a good opportunity to study magnetization reversal in the absence of grain boundaries and other microstructural complexities inherent to sintered magnets.

In this study, we synthesis large single-crystal magnets of SmCo5 with high-quality surfaces to investigate their magnetization reversal process. After surface treatment by electro-polishing, the SmCo5 magnets exhibit a significantly increased coercivity reaching values close to 1 T, and are two to ten times larger in size compared to previous reports with similar coercivity (see Figure). We delve into the origin of this large coercivity and examine the detailed influence of surface conditions and different nucleation processes. We discuss the effect of type-I (local depining) and type-II (true nucleation) nucleus and their impact in magnetization reversal of our objects. Lastly, we explore the angular dependence of coercivity in these ideal objects, assessing the method's applicability for more complex systems like sintered magnets. In summary, we present ideal single crystal permanent magnet of SmCo5 which can help us understand deeper the coercivity mechanism (nucleation, pinning) and the role of surface (im)perfection [3].

References

[1] Chikazumi, JMMM 54-57, 1551 (1986)

[2] J. Li, H. Sepehri-Amin, et al , STAM 22:1 386-403 (2021)

[3] H. Zhang, A. Aubert et al. JALCOM 993 174570 (2024)

Acknowledgement:

This work was supported by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation), Project ID no. 405553726-TRR 270 and the National Key R&D Program of China (2023YFB3508500).