Presentation Information

[O10-4]Preparation of magnetically alignable Sm-Co alloy nanoparticles by wet-jet milling

*Kwangjae Park1, Yusuke Hirayama1 (1. National Institute of Advanced Industrial Science and Technology (AIST) (Japan))

Keywords:

Sm-Co alloys,nanoparticles,wet-jet milling,crystallographic orientation,anisotropic magnetic behavior

The anisotropic fine rare-earth alloy particles with high coercivity and high remanent magnetization are promising optimal precursor materials for developing high-performance permanent magnets. In a previous study, we successfully synthesized anisotropic Sm-Co nanopowder with an average particle size of 60 nm using a low-oxygen induction thermal plasma process [1]. The Sm-Co nanopowder consisted of a few types of Sm-Co alloys particles, SmCo5, Sm2Co17, and SmCo3. The volume fraction of the SmCo5 phase was estimated to be 34 wt% based on X-ray diffraction (XRD) measurements [2].

In order to improve the coercivity of the Sm-Co nanopowder by increasing the volume fraction of SmCo5 phase, we investigated the effect of heat treatment on its magnetic properties [2]. After annealing at 900°C in an Ar atmosphere, the volume fraction of the SmCo5 phase increased to 58 wt%, and the coercivity improved to 1.8 T. However, the heat-treated Sm-Co nanopowder exhibited low crystallographic alignment and weak anisotropic magnetic behavior under an external magnetic field. This was attributed to severe necking between nanoparticles during heat treatment, leading to the formation of isotropic polycrystalline Sm-Co powder.

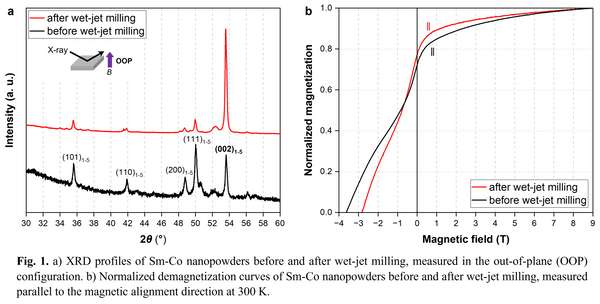

To enhance the anisotropic magnetic behavior of the heat-treated Sm-Co nanopowder, we employed wet-jet milling, a technique that utilizes a high-speed injection pressure of approximately 200 MPa, to break up the necking between nanoparticles. The heat-treated Sm-Co nanopowder with a coercivity of 3.6 T was pulverized using wet-jet milling. The XRD profiles of magnetically aligned Sm-Co nanopowder revealed a significant increase in the intensity of the SmCo5 (002) peak after wet-jet milling, as shown in Fig. 1a, indicating that the SmCo5 nanoparticles—after necking removal—were sufficiently oriented by the external magnetic field. Furthermore, magnetic measurements demonstrated that the wet-jet milled Sm-Co nanopowder exhibited a higher Mr/M@9T ratio, as shown in Fig. 1b, indicating improved anisotropic magnetic behavior. Based on these results, we conclude that wet-jet milling is an effective method for enhancing the anisotropic magnetic behavior of rare-earth alloy nanoparticles.

References

[1] K. Park, Y. Hirayama, M. Shigeta, Z. Liu, M. Kobashi, K. Takagi, J. Alloys Compd. 882 (2021) 160633.

[2] K. Park, Y. Hirayama, Adv. Powder Technol. 34 (2023) 104238.

In order to improve the coercivity of the Sm-Co nanopowder by increasing the volume fraction of SmCo5 phase, we investigated the effect of heat treatment on its magnetic properties [2]. After annealing at 900°C in an Ar atmosphere, the volume fraction of the SmCo5 phase increased to 58 wt%, and the coercivity improved to 1.8 T. However, the heat-treated Sm-Co nanopowder exhibited low crystallographic alignment and weak anisotropic magnetic behavior under an external magnetic field. This was attributed to severe necking between nanoparticles during heat treatment, leading to the formation of isotropic polycrystalline Sm-Co powder.

To enhance the anisotropic magnetic behavior of the heat-treated Sm-Co nanopowder, we employed wet-jet milling, a technique that utilizes a high-speed injection pressure of approximately 200 MPa, to break up the necking between nanoparticles. The heat-treated Sm-Co nanopowder with a coercivity of 3.6 T was pulverized using wet-jet milling. The XRD profiles of magnetically aligned Sm-Co nanopowder revealed a significant increase in the intensity of the SmCo5 (002) peak after wet-jet milling, as shown in Fig. 1a, indicating that the SmCo5 nanoparticles—after necking removal—were sufficiently oriented by the external magnetic field. Furthermore, magnetic measurements demonstrated that the wet-jet milled Sm-Co nanopowder exhibited a higher Mr/M@9T ratio, as shown in Fig. 1b, indicating improved anisotropic magnetic behavior. Based on these results, we conclude that wet-jet milling is an effective method for enhancing the anisotropic magnetic behavior of rare-earth alloy nanoparticles.

References

[1] K. Park, Y. Hirayama, M. Shigeta, Z. Liu, M. Kobashi, K. Takagi, J. Alloys Compd. 882 (2021) 160633.

[2] K. Park, Y. Hirayama, Adv. Powder Technol. 34 (2023) 104238.