Presentation Information

[O11-1]Origin of high coercivity in post-sinter annealed Cu-doped Sm(Fe,Ti,V)12-based sintered magnets

*JIASHENG ZHANG1, Xin Tang1, Tadakatsu OHKUBO1, Kazuhiro Hono1, SEPEHRI-AMIN Hossein1 (1. National Institute for Materials Science (Japan))

Keywords:

1:12 sintered magnets,Post-sinter annealing,Intergranular phase,Coercivity

Research on SmFe12-based (1:12) compounds has been revived due to their excellent intrinsic magnetic properties [1]. However, how to transfer the intrinsic magnetic properties to the high extrinsic performance in bulk 1:12 magnet is still a major problem. Recent studies have been demonstrated coercivities of 0.8 – 1.0 T in textured 1:12 sintered magnets [2, 3]. Note that the reported coercivity is still less than 10% of the anisotropy field of the 1:12 phase. By introducing Cu, a record high coercivity of 1.4 T was obtained due to the formation of Cu-rich intergranular phases between 1:12 grains [4]. Therefore, microstructure engineering is essential to further increase the coercivity. Post-sinter annealing (PSA) is effective in forming the continuous intergranular phase in Nd-Fe-B sintered magnets [5]. The question is whether PSA can have a similar influence in SmFe12-based sintered magnets to further increase the coercivity.

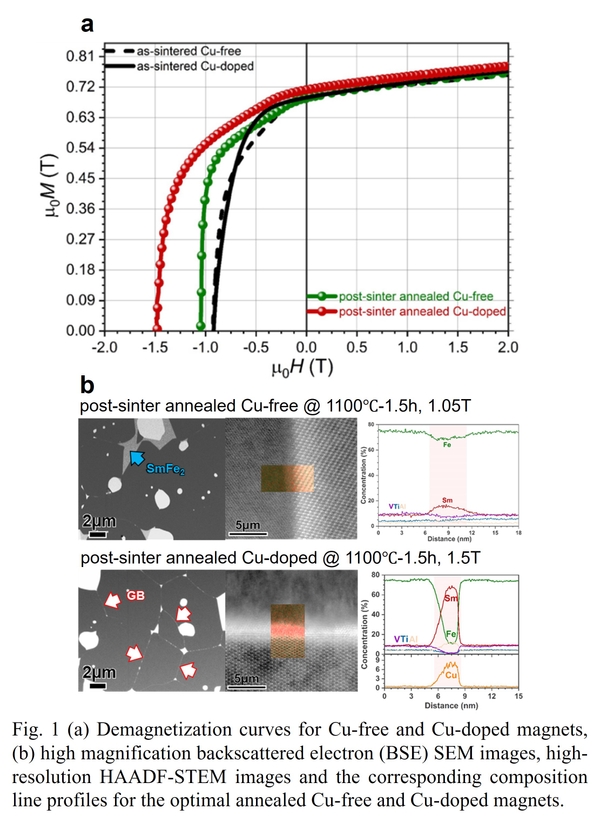

In this work, Sm8Fe77Ti5V8Al2 at. % (named Cu-free) and Sm8Fe76.5Ti5V8Al2Cu0.5 at. % (named Cu-doped) sintered magnets were prepared by conventional powder processing method. The magnets were prepared by sintering at 1100 ℃ for 1.5 h, and followed by PSA at 500 - 1100 ℃ for 1.5 h. The coercivity of the Cu-doped magnet was significantly enhanced from 0.9 T to 1.48 T by PSA at 1100 ℃ for 1.5 h, compared to 0.93 T to 1.05 T in the referenced Cu-free magnet (Fig. 1a). Detailed microstructure characterizations were conducted to understand the origin of the coercivity increase. The existence of ferromagnetic SmFe2 in post-sinter annealed Cu-free sample was observed by XRD, TEM, and Lorentz microscopy while it could be fully eliminated in the optimally annealed Cu-doped sample. Moreover, thick and continuous Sm-rich intergranular phase with an excellent interconnection was observed in the optimally annealed Cu-doped magnet (Fig. 1b). Formation of thick Sm-rich intergranular phases can reduce the exchange-coupling between 1:12 grains resulting in a coercivity enhancement. This work indicates that the addition of Cu is beneficial to realize a large coercivity in optimally annealed 1:12 sintered magnets by suppressing the SmFe2 phase and forming the Sm-rich intergranular phase.

[1] A. Gabay, G. Hadjipanayis. Scripta Mater., 154 (2018) 284-288.

[2] K. Otsuka, et al. Mater. Trans., 62 (2021) 887-891.

[3] J. Zhang, et al. Acta Mater., 217 (2021) 117161.

[4] A. Srinithi, et al. Acta Mater., 256 (2023) 119111.

[5] R.K. Mishra, et al. J. Appl. phys., 59 (1986) 2244-2246.

In this work, Sm8Fe77Ti5V8Al2 at. % (named Cu-free) and Sm8Fe76.5Ti5V8Al2Cu0.5 at. % (named Cu-doped) sintered magnets were prepared by conventional powder processing method. The magnets were prepared by sintering at 1100 ℃ for 1.5 h, and followed by PSA at 500 - 1100 ℃ for 1.5 h. The coercivity of the Cu-doped magnet was significantly enhanced from 0.9 T to 1.48 T by PSA at 1100 ℃ for 1.5 h, compared to 0.93 T to 1.05 T in the referenced Cu-free magnet (Fig. 1a). Detailed microstructure characterizations were conducted to understand the origin of the coercivity increase. The existence of ferromagnetic SmFe2 in post-sinter annealed Cu-free sample was observed by XRD, TEM, and Lorentz microscopy while it could be fully eliminated in the optimally annealed Cu-doped sample. Moreover, thick and continuous Sm-rich intergranular phase with an excellent interconnection was observed in the optimally annealed Cu-doped magnet (Fig. 1b). Formation of thick Sm-rich intergranular phases can reduce the exchange-coupling between 1:12 grains resulting in a coercivity enhancement. This work indicates that the addition of Cu is beneficial to realize a large coercivity in optimally annealed 1:12 sintered magnets by suppressing the SmFe2 phase and forming the Sm-rich intergranular phase.

[1] A. Gabay, G. Hadjipanayis. Scripta Mater., 154 (2018) 284-288.

[2] K. Otsuka, et al. Mater. Trans., 62 (2021) 887-891.

[3] J. Zhang, et al. Acta Mater., 217 (2021) 117161.

[4] A. Srinithi, et al. Acta Mater., 256 (2023) 119111.

[5] R.K. Mishra, et al. J. Appl. phys., 59 (1986) 2244-2246.