Presentation Information

[O11-2]The effect Ag on phase transformation and magnetic properties in SmFe12-based composition

Maria Takeuchi1, Aaron Dextre Zamalloa1, Esmaeil Adabifiroozjaei2, Leopoldo Molina-Luna2, Oliver Gutfleisch1, *Pelin Tozman1 (1. Functional Materials, Institute of Materials Science, Technische Universität Darmstadt, 64287 Darmstadt (Germany), 2. Advanced Electron Microscopy Division, Institute of Material Science, Technical University of Darmstadt, 64287 Darmstadt (Germany))

Keywords:

SmFe12-based,Intergranular phase,Melt spinning,Structure

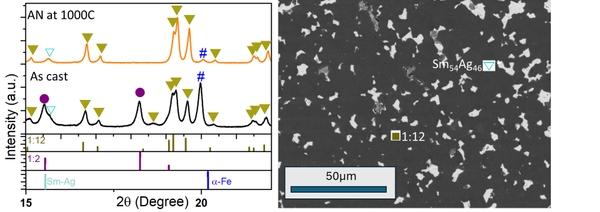

The renewed interest in SmFe12-based compounds is driven by their superior intrinsic magnetic properties, making them a promising candidate for replacing Nd-Fe-B magnets, particularly in high-temperature applications [1]. However, a key challenge for these compounds is achieving an optimal microstructure in which hard magnetic grains are isolated by an intergranular phase while maintaining a minimal amount of phase stabilizer within the hard magnetic grains to preserve high magnetization [2]. Overcoming these challenges is particularly difficult due to the lack of equilibrium between the hard magnetic 1:12 phase and low-melting-point phases in the Sm-Fe-V phase diagrams, especially in the M-lean region where the M content is below 15 at.%.Therefore, in this study, we selected V over Ti in our composition design, as V promotes less twin formation, which helps higher coercivity [3]. The V content was kept below 15 at.% to maximize the magnetization, while Zr was substituted at the Sm site to maintain the 1:12 phase stability. Additionally, Ag was introduced to form a non-ferromagnetic Sm-Ag intergranular phase, which does not enter the 1:12 crystal structure [4].In the first part, we will discuss the effects of annealing and composition on phase formation, as well as the optimal composition for stabilizing the 1:12 phase, as illustrated in Fig. 1. In the second part, we will examine the impact of wheel speed, annealing, and composition on phase formation and extrinsic magnetic properties. For instance, reducing the V content results in Ms between 0.8T and 1T, while the Sm-Ag intergranular phase contributes to achieving µ0Hc of 0.6T–0.77T. Interestingly, ribbons predominantly containing the SmFe3-type phase also exhibit a moderate coercivity of 0.76T. Furthermore, machine learning algorithms are applied to optimize the experimental process, maximizing extrinsic magnetic properties and identifying desirable phases to enhance coercivity.

Fig. 1 The XRD and BSE image of Sm15.4Zr1.4Fe71.5V9.23Ag2.85 ingot.

References: [1] P. Tozman et al, Scr. Mater. 194 (2021) 113686. [2] J. S. Zhang et al., Acta Mater. 238 (2022) 118228.[3] P. Tozman et al., Scr. Mater. 258 (2025) 116491[4] O. Takeda et al., J. Magn. Magn. Mater. 542 (2022) 168.

Acknowledgment: The work leading to this invention has received funding from the European Research Council under the European Union's Seventh Framework Programme (FP7/2007-2013) / ERC starting grant agreement no 57400056 and by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation), Project ID No 405553726, CRC/TRR 270.

Fig. 1 The XRD and BSE image of Sm15.4Zr1.4Fe71.5V9.23Ag2.85 ingot.

References: [1] P. Tozman et al, Scr. Mater. 194 (2021) 113686. [2] J. S. Zhang et al., Acta Mater. 238 (2022) 118228.[3] P. Tozman et al., Scr. Mater. 258 (2025) 116491[4] O. Takeda et al., J. Magn. Magn. Mater. 542 (2022) 168.

Acknowledgment: The work leading to this invention has received funding from the European Research Council under the European Union's Seventh Framework Programme (FP7/2007-2013) / ERC starting grant agreement no 57400056 and by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation), Project ID No 405553726, CRC/TRR 270.