Presentation Information

[O11-4]In-Depth investigation of the sub-micronic equiaxed grain microstructure of a NdFeB permanent magnet fabricated by Laser Powder Bed Fusion

*Aymeric Wolz1, Jean-Paul Garandet1,2, Camille Flament1, Olivier Tosoni1 (1. CEA (French Alternative Energies and Atomic Energy Commission) (France), 2. UGA (Grenoble Alpes University) (France))

Keywords:

Laser Powder Bed Fusion (LPBF),Additive manufacturing,NdFeB,Microstructure investigation,Columnar to equiaxed transition (CET)

Laser Powder Bed Fusion (LPBF) has been identified as an interesting technique for the manufacturing of high coercivity NdFeB magnets thanks to the emergence of sub-micronic microstructures [1]. However, most studies have focused on commercial MQP-S powder whose chemical composition is not optimized for the formation of a Nd-rich intergranular phase, thus resulting in poor magnetic properties [2]. In this work, magnets have been elaborated using a specific and unique powder fabricated with an in-house experimental pilot line allowing to adapt both the size (in the case of this study a narrowly-distributed powder with a volumic D50 of 40 μm) and the chemical composition of the material as desired.

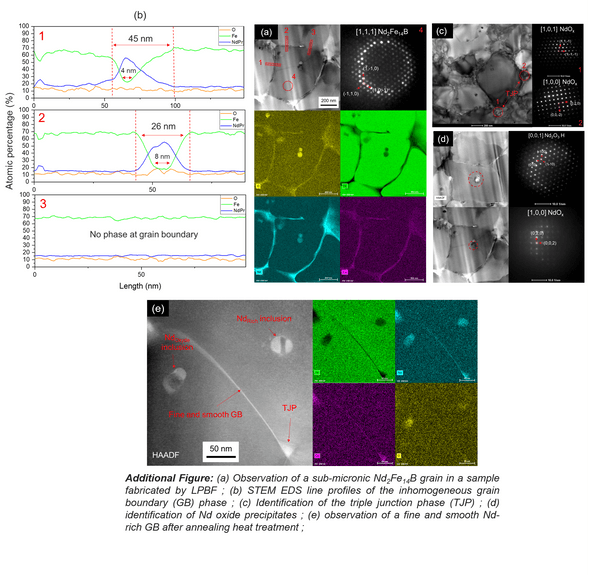

The microstructure of the magnets has been characterized down to the nano-scale using TEM analyses. It is composed of sub-micronic Nd2Fe14B grains ranging from 100-200 nm to 1-2 μm and multiple Nd-rich phases at grain boundaries. Interestingly, there seems to be a NdOx phase (Fm3m structure) mainly present at the triple junctions (TJ) with a lattice parameter of circa 5.5 angstroms, while the fine grain boundaries are composed of metallic Nd with traces of Cu and Ga. As for sintered magnets, non-homogeneous grain boundaries have been identified in the as-built materials, which prevents high coercivity to be obtained. However, the magnetic properties can be improved by annealing heat treatments around 500-600°C that allow the grain boundary phase to reorganize. This effect is made possible thanks to the presence of addition elements (in particular Cu and Ga) which lower the melting temperature of the Nd-rich phase [3].

Multiple precipitates have been observed inside of the grains sizing from 10 to 100 nm. They have been identified either as NdOx Fm3m but this time with a lattice parameter of circa 5.2 angstroms, either as Nd2O3 P63/mmc. These results agree with reference works on sintered magnets [4].

In this context, the origin of the formation of an almost fully equiaxed microstructure has been investigated. Indeed, in LPBF fabrications, the formation of columnar grains is generally preponderant, as the formation of equiaxed grains is not expected due to the strong thermal gradients generated during the process. Using both a numerical model to provide information on the cooling conditions of the alloy during LPBF [5] and experimental observations on crystallographic orientations between Nd oxide precipitates and Nd2Fe14B, it has been suggested that the oxides could act as nuclei for the formation of the Nd2Fe14B phase.

Such a result could be of strong interest for future optimization of the LPBF process for Nd2Fe14B magnets as Nd oxides are naturally present in the alloy due to fabrication conditions of the powder, and as sub-micronic grains are beneficial for the formation of high coercivity magnets.

References:

[1] O. Tosoni et al., « High-coercivity copper-rich Nd-Fe-B magnets by powder bed fusion using laser beam method », Additive Manufacturing, vol. 64, p. 103426, févr. 2023, doi: 10.1016/j.addma.2023.103426.

[2] J. Wu et al., « Amorphous-crystalline nanostructured Nd-Fe-B permanent magnets using laser powder bed fusion: Metallurgy and magnetic properties », Acta Materialia, vol. 259, p. 119239, oct. 2023, doi: 10.1016/j.actamat.2023.119239.

[3] W. F. Li, T. Ohkubo, T. Akiya, H. Kato, et K. Hono, « The role of Cu addition in the coercivity enhancement of sintered Nd-Fe-B permanent magnets», Journal of Materials Research, vol. 24, no 2, p. 413-420, feb. 2009, doi: 10.1557/JMR.2009.0041.

[4] Y. Shinba, T. J. Konno, K. Ishikawa, K. Hiraga, et M. Sagawa, « Transmission electron microscopy study on Nd-rich phase and grain boundary structure of Nd–Fe–B sintered magnets », Journal of Applied Physics, vol. 97, no 5, p. 053504, févr. 2005, doi: 10.1063/1.1851017.

[5] A. Wolz, R. Caniou, O. Tosoni, C. Rado, et J.-P. Garandet, « On the Effect of Cooling Parameters on Solidification Structure in NdFeB Alloys », Advanced Engineering Materials, vol. n/a, no n/a, p. 2400978, doi: 10.1002/adem.202400978.

The microstructure of the magnets has been characterized down to the nano-scale using TEM analyses. It is composed of sub-micronic Nd2Fe14B grains ranging from 100-200 nm to 1-2 μm and multiple Nd-rich phases at grain boundaries. Interestingly, there seems to be a NdOx phase (Fm3m structure) mainly present at the triple junctions (TJ) with a lattice parameter of circa 5.5 angstroms, while the fine grain boundaries are composed of metallic Nd with traces of Cu and Ga. As for sintered magnets, non-homogeneous grain boundaries have been identified in the as-built materials, which prevents high coercivity to be obtained. However, the magnetic properties can be improved by annealing heat treatments around 500-600°C that allow the grain boundary phase to reorganize. This effect is made possible thanks to the presence of addition elements (in particular Cu and Ga) which lower the melting temperature of the Nd-rich phase [3].

Multiple precipitates have been observed inside of the grains sizing from 10 to 100 nm. They have been identified either as NdOx Fm3m but this time with a lattice parameter of circa 5.2 angstroms, either as Nd2O3 P63/mmc. These results agree with reference works on sintered magnets [4].

In this context, the origin of the formation of an almost fully equiaxed microstructure has been investigated. Indeed, in LPBF fabrications, the formation of columnar grains is generally preponderant, as the formation of equiaxed grains is not expected due to the strong thermal gradients generated during the process. Using both a numerical model to provide information on the cooling conditions of the alloy during LPBF [5] and experimental observations on crystallographic orientations between Nd oxide precipitates and Nd2Fe14B, it has been suggested that the oxides could act as nuclei for the formation of the Nd2Fe14B phase.

Such a result could be of strong interest for future optimization of the LPBF process for Nd2Fe14B magnets as Nd oxides are naturally present in the alloy due to fabrication conditions of the powder, and as sub-micronic grains are beneficial for the formation of high coercivity magnets.

References:

[1] O. Tosoni et al., « High-coercivity copper-rich Nd-Fe-B magnets by powder bed fusion using laser beam method », Additive Manufacturing, vol. 64, p. 103426, févr. 2023, doi: 10.1016/j.addma.2023.103426.

[2] J. Wu et al., « Amorphous-crystalline nanostructured Nd-Fe-B permanent magnets using laser powder bed fusion: Metallurgy and magnetic properties », Acta Materialia, vol. 259, p. 119239, oct. 2023, doi: 10.1016/j.actamat.2023.119239.

[3] W. F. Li, T. Ohkubo, T. Akiya, H. Kato, et K. Hono, « The role of Cu addition in the coercivity enhancement of sintered Nd-Fe-B permanent magnets», Journal of Materials Research, vol. 24, no 2, p. 413-420, feb. 2009, doi: 10.1557/JMR.2009.0041.

[4] Y. Shinba, T. J. Konno, K. Ishikawa, K. Hiraga, et M. Sagawa, « Transmission electron microscopy study on Nd-rich phase and grain boundary structure of Nd–Fe–B sintered magnets », Journal of Applied Physics, vol. 97, no 5, p. 053504, févr. 2005, doi: 10.1063/1.1851017.

[5] A. Wolz, R. Caniou, O. Tosoni, C. Rado, et J.-P. Garandet, « On the Effect of Cooling Parameters on Solidification Structure in NdFeB Alloys », Advanced Engineering Materials, vol. n/a, no n/a, p. 2400978, doi: 10.1002/adem.202400978.