Presentation Information

[O12-2]Rare-earth free MnBi magnets: recent developments in combining severe plastic deformation with thermomagnetic processing

*K.S. Anand1, Martin Kraus1, Stefan Wurster1, Michael Meindlhumer2, Andrea Bachmaier1 (1. Erich Schmid Institute, Austrian Academy of Sciences (Austria), 2. Department of Materials Science, Montanuniversität Leoben (Austria))

Keywords:

rare-earth free,solid state processing,severe plastic deformation

Gap-magnets, i.e. magnetic materials bridging the performance and economic gap between ferrite-based and rare-earth element based magnets, have garnered significant focus in recent years. A possible gap magnet free of rare-earth elements identified so far is the alpha-phase of MnBi, which is difficult to synthesize due to the different characteristics of the pure components. High oxidation preference for Mn powders and large difference in melting point between Mn and Bi exclude many conventional synthesis approaches.

Recent research provided a promising route via severe plastic deformation of pure bulk components in powder form using the high-pressure torsion (HPT) technique and subsequent thermomagnetic annealing to prepare MnBi magnets containing a decent fraction of the alpha-phase. The elemental Mn and Bi powders get directly consolidated during HPT processing, which enables to obtain bulk samples. Although the synthesis of the alpha-phase of MnBi is possible by HPT, technical use would require close to 100 wt.% of this phase, especially for exchange-coupling with a soft magnetic phase to improve saturation magnetization.

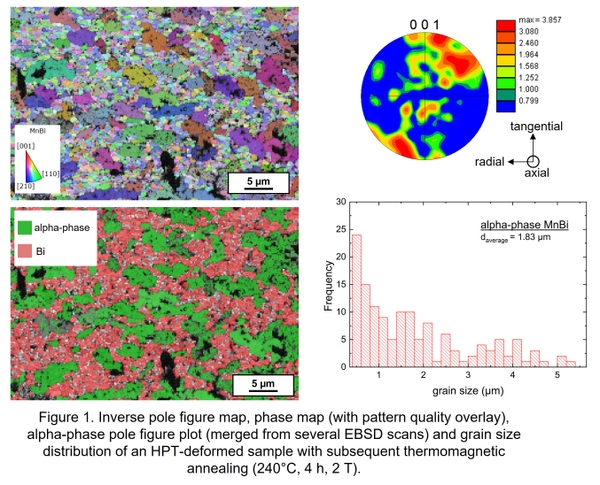

In this talk, our recent developments in HPT processing and optimization of MnBi based magnets considering various possible process parameters (parameters for powder compaction, temperature for deformation and annealing, applied external magnetic field, processing times) are presented. Another topic covered is the process-structure-property relationships that link chemistry, synthesis and processing parameters with microstructure evolution and magnetic properties. An emphasis is put on detailed characterization of the microstructure since it strongly influences the magnetic properties. Therefore, the evolving parameters of microstructures, for example grain size and texture, are studied in detail by backscattered electron imaging, electron backscattered diffraction (EBSD) as well as x-ray diffraction utilizing high energy synchrotron radiation and correlated to the magnetic properties measured by SQUID-magnetometry.

As an example, the microstructure characterized by EBSD (inverse pole figure, phase map, pole figure plot and alpha-phase grain size distribution) of an HPT-deformed sample with subsequent thermomagnetic annealing is shown in Figure 1. After 4 h of annealing at 240°C in vacuum under a magnetic field of 2 T, the sample consist of 45 wt% alpha-phase with coercivity Hc of 1.92 kOe, a remanence Mr of 12.6 emu/g and a saturation magnetization Ms of 35.6 emu/g. The grain size of the alpha-phase is ultrafine grained with a texture (c-axis preferably oriented along the axial direction of the HPT disc). Prolonged annealing for 12 h with same processing and thermomagnetic parameters only slightly increases the alpha-phase amount with similar Mr and Ms values and no change in texture is observed. Grain coarsening, however, reduces the coercivity Hc. Long time annealing increases the alpha-phase content higher than 70 wt%.

These detailed analyses of process-structure-property relationships performed in this study can be used to develop optimization strategies for the synthesis of MnBi magnets with higher fraction of the alpha-phase by HPT and thermomagnetic processing.

This research was funded by the Austrian Science Fund (FWF) 10.55776/TAI4821824. We acknowledge DESY (Hamburg, Germany), a member of the Helmholtz Association HGF, for the provision of experimental facilities. Parts of this research were carried out at PETRA III and we would like to thank M. Blankenburg for assistance in using P21.2. Beamtime was allocated for proposal I-20220454 EC.

Recent research provided a promising route via severe plastic deformation of pure bulk components in powder form using the high-pressure torsion (HPT) technique and subsequent thermomagnetic annealing to prepare MnBi magnets containing a decent fraction of the alpha-phase. The elemental Mn and Bi powders get directly consolidated during HPT processing, which enables to obtain bulk samples. Although the synthesis of the alpha-phase of MnBi is possible by HPT, technical use would require close to 100 wt.% of this phase, especially for exchange-coupling with a soft magnetic phase to improve saturation magnetization.

In this talk, our recent developments in HPT processing and optimization of MnBi based magnets considering various possible process parameters (parameters for powder compaction, temperature for deformation and annealing, applied external magnetic field, processing times) are presented. Another topic covered is the process-structure-property relationships that link chemistry, synthesis and processing parameters with microstructure evolution and magnetic properties. An emphasis is put on detailed characterization of the microstructure since it strongly influences the magnetic properties. Therefore, the evolving parameters of microstructures, for example grain size and texture, are studied in detail by backscattered electron imaging, electron backscattered diffraction (EBSD) as well as x-ray diffraction utilizing high energy synchrotron radiation and correlated to the magnetic properties measured by SQUID-magnetometry.

As an example, the microstructure characterized by EBSD (inverse pole figure, phase map, pole figure plot and alpha-phase grain size distribution) of an HPT-deformed sample with subsequent thermomagnetic annealing is shown in Figure 1. After 4 h of annealing at 240°C in vacuum under a magnetic field of 2 T, the sample consist of 45 wt% alpha-phase with coercivity Hc of 1.92 kOe, a remanence Mr of 12.6 emu/g and a saturation magnetization Ms of 35.6 emu/g. The grain size of the alpha-phase is ultrafine grained with a texture (c-axis preferably oriented along the axial direction of the HPT disc). Prolonged annealing for 12 h with same processing and thermomagnetic parameters only slightly increases the alpha-phase amount with similar Mr and Ms values and no change in texture is observed. Grain coarsening, however, reduces the coercivity Hc. Long time annealing increases the alpha-phase content higher than 70 wt%.

These detailed analyses of process-structure-property relationships performed in this study can be used to develop optimization strategies for the synthesis of MnBi magnets with higher fraction of the alpha-phase by HPT and thermomagnetic processing.

This research was funded by the Austrian Science Fund (FWF) 10.55776/TAI4821824. We acknowledge DESY (Hamburg, Germany), a member of the Helmholtz Association HGF, for the provision of experimental facilities. Parts of this research were carried out at PETRA III and we would like to thank M. Blankenburg for assistance in using P21.2. Beamtime was allocated for proposal I-20220454 EC.